| Layer count | 1-6 layers (flex area) and up to 20 | ||

|---|---|---|---|

| Material | Polyimide, FR-4, and FR-4 High-Tg | ||

| Board Thickness | Flexible area: 0.05mm – 0.3mm, | ||

| Rigid area: 0.5mm – 3.2mm | 1*1mm | ||

| Copper Thickness | 1/3 Oz (12 µm) – 2 Oz (70 µm), depends on design and material requirements | ||

| Minimum Trace Width/Spacing | 3mil/3mil (0.0762mm/0.0762mm) or better, depending on design and materials | ||

| Minimum Hole Size | 0.2mm (8mil) or larger, depending on layer count | ||

| Aspect Ratio | 10:1 or better | ||

| Max Board Size | 400mm x 500mm | ||

| Surface Finish | ENIG, Immersion Silver, OSP, HASL, Lead-Free HASL, etc | ||

| Solder Mask | Green, Blue, Yellow, Black, Red, White, and other colors | ||

| Solder Mask Resolution | 4mil (0.1mm) minimum | ||

| Solder Mask Registration | ±2mil (±0.0508mm) | ||

| Silkscreen Color | White, Black, Yellow | ||

| Coverlay | Polyimide, with or without adhesive, depending on the application requirements | ||

| Plated Through Holes (PTH) | Yes | ||

| Blind & Buried Vias (BBV) | Yes | ||

| Controlled Impedance | Yes, can be achieved in both rigid and flexible areas | ||

| Stiffeners | FR-4, Polyimide, or Stainless Steel, installed to provide support and rigidity when needed | ||

| Electrical Testing | Continuity & isolation, impedance control, Hi-Pot, etc. | ||

| Mechanical Assembly | Supported | ||

| Certification | ISO9001:2015;ISO13485:2016;ROHS,UL 94v0, IPC-600G classll and IPC-6012B classll standard |

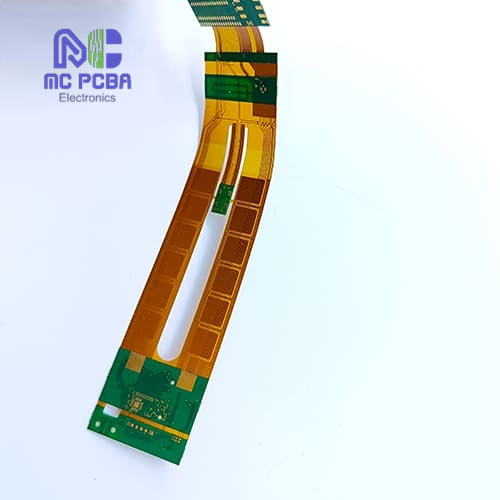

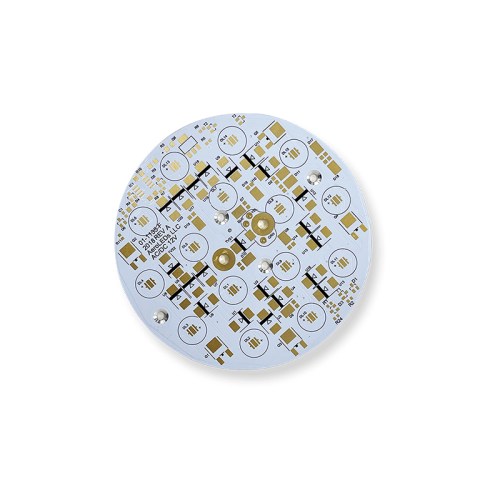

High-Performance Rigid-Flex PCB for Hybrid Circuit Solutions – MCPCBA Manufacturing

$100.00

MCPCBA offers premium Rigid-Flex PCBs, combining the durability of rigid boards with the adaptability of flexible circuits. Perfect for hybrid electronic applications, our Rigid-Flex PCBs are designed to optimize space and reliability, adhering to ISO9001:2015 and ROHS standards. Ideal for complex, multi-functional devices.

Request for Quotation

Отзывы

Отзывов пока нет.